How to Boost Plant Utilisation For Maximum Efficiency

In today’s fast-paced world of civil construction, maximising the utilisation of plant and equipment is essential for operational efficiency and project success.

Properly measuring and optimising plant utilisation reduces costs, improves productivity, and ensures the smooth execution of construction projects. In this article, we will explore key strategies and tools that can assist operations managers, project managers, and fleet managers in effectively measuring and boosting plant utilisation.

Implement a comprehensive tracking system:

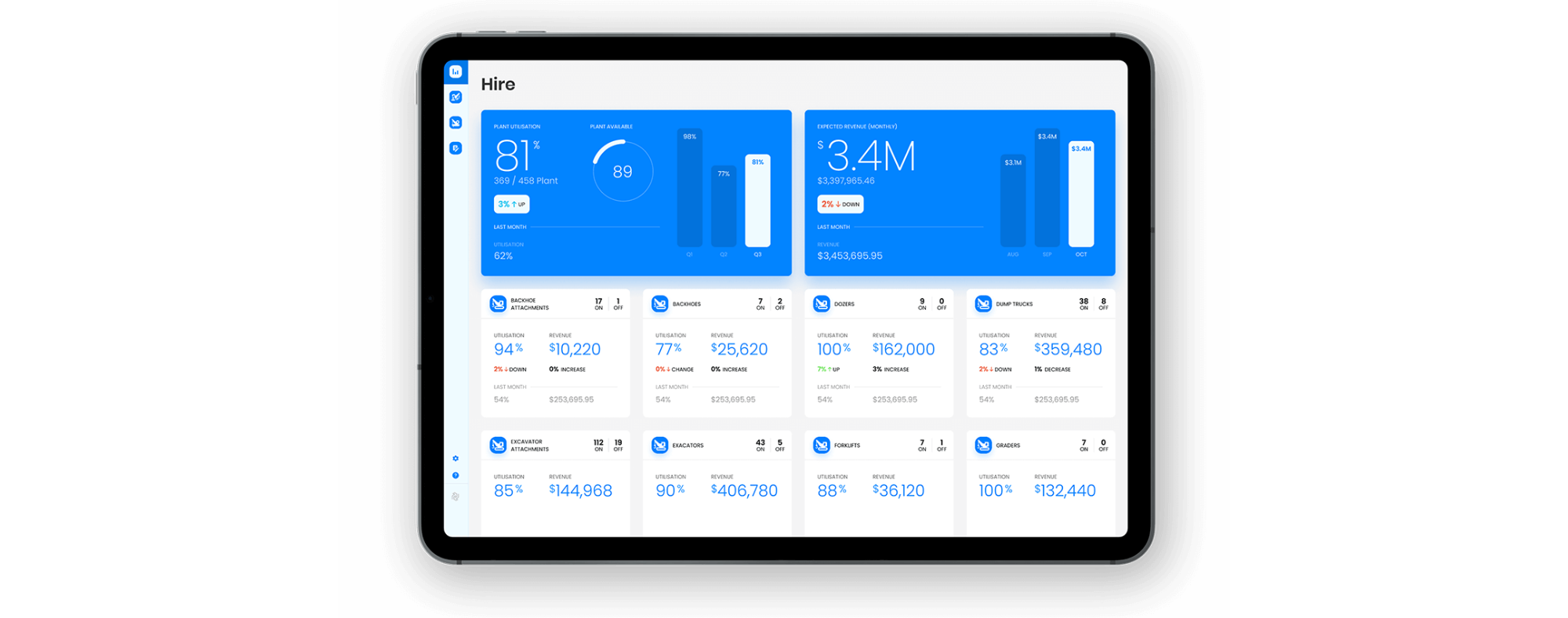

To measure plant utilisation accurately and effectively, it is essential to establish a robust tracking system within the organisation. This can be achieved through the implementation of an all-in-one consolidated software solution specifically designed for the construction industry. By digitising operational tasks and consolidating them into a single platform, this software provides real-time monitoring of plant utilisation metrics. It offers valuable insights into equipment availability, patterns of usage, and instances of downtime. Armed with this detailed data, managers can identify underutilised assets, analyse utilisation patterns, and make informed decisions to optimise the deployment of equipment. The utilisation tracking system provided by the all-in-one consolidated software empowers managers with the information they need to maximise productivity, minimise downtime, and ultimately improve the overall efficiency of their construction operations.

Set utilisation targets:

Setting utilisation targets is an essential strategy for driving performance and enhancing efficiency within the construction industry. Operations managers can effectively motivate their teams by establishing realistic goals for plant utilisation. These targets can be derived from industry benchmarks or historical data specific to the organisation. Regular monitoring of progress and providing constructive feedback to teams ensures alignment with the utilisation goals. By implementing this approach, companies can foster a culture of continuous improvement and encourage their workforce to maximise equipment usage, resulting in increased productivity and cost savings. Setting utilisation targets provides a clear direction for operations managers and serves as a powerful tool for enhancing overall operational performance.

Conduct regular equipment maintenance:

Unplanned equipment breakdowns have a significant negative impact on plant utilisation and disrupt construction operations. To mitigate the risk of such disruptions, it is crucial to adopt a proactive approach to equipment maintenance. Implementing a well-structured preventive maintenance schedule is essential in identifying potential issues before they escalate into major problems and lead to unplanned downtime. By adhering to these maintenance schedules and conducting regular inspections, managers can effectively keep the equipment in optimal condition, reduce the likelihood of breakdowns, and ultimately maximise plant utilisation. This proactive approach to maintenance ensures that any potential issues are addressed promptly, minimising the risk of unexpected equipment failures and maximising the overall efficiency of the construction operations.

Optimise scheduling and coordination:

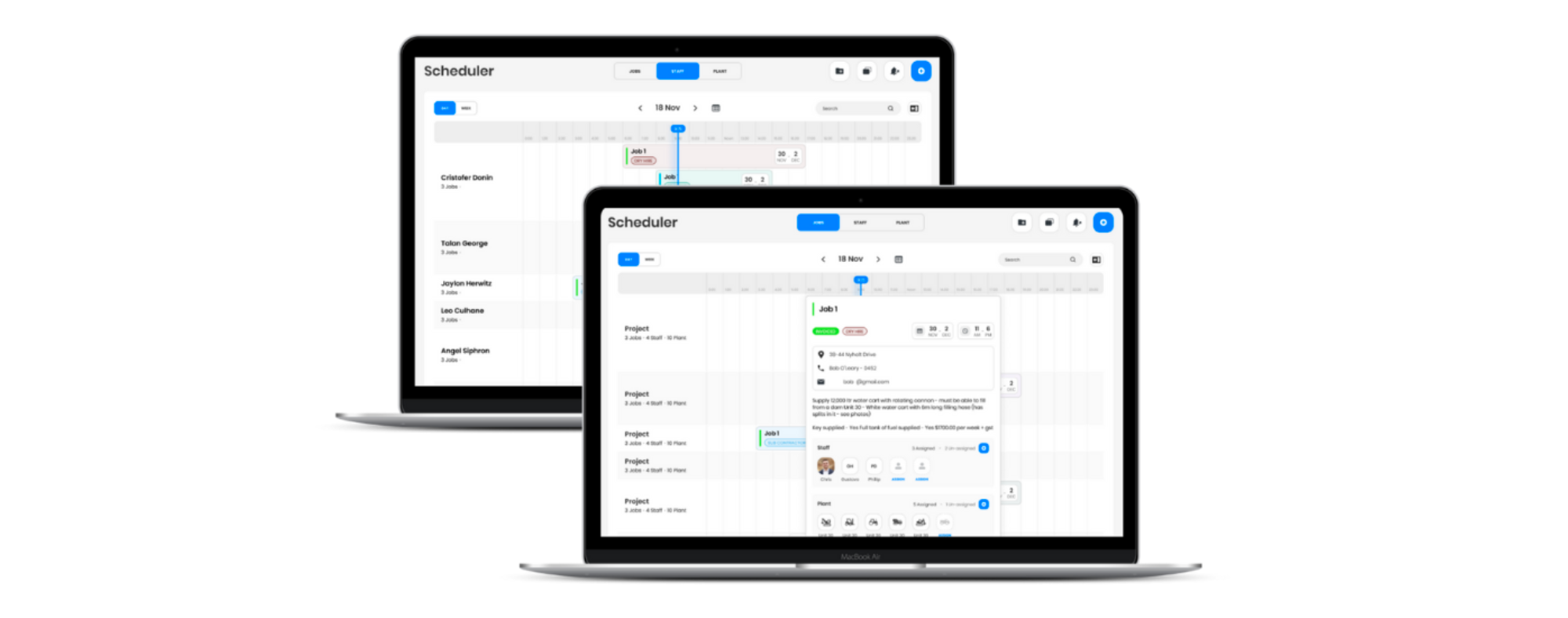

Optimising scheduling and coordination is a critical factor in maximising equipment utilisation rates. By carefully analysing project timelines and equipment requirements, managers can ensure that machinery is allocated effectively and efficiently. This involves avoiding conflicts such as double-bookings or excessive idle time, which can significantly impact overall plant utilisation. To streamline these processes and enhance scheduling accuracy, utilising an all-in-one consolidated software solution is highly beneficial. This software provides real-time scheduling updates and resource allocation capabilities, allowing managers to make informed decisions and optimise plant utilisation. With the ability to track equipment availability, monitor project timelines, and adjust schedules as needed, the software empowers managers to maximise the productivity of their equipment, reduce downtime, and achieve higher overall utilisation rates. By integrating scheduling and coordination within a comprehensive software platform, companies can streamline their operations and achieve greater efficiency in managing their equipment resources.

Embrace data-driven decision-making:

Embracing data-driven decision-making is essential for optimising plant utilisation. All-in-one consolidated software makes this possible as it provides managers with access to comprehensive data that captures and analyses various aspects of equipment usage. Leveraging this valuable information, managers gain insights into usage patterns, identify bottlenecks, and make strategic adjustments to maximise plant utilisation. By adopting a data-driven approach, managers can proactively plan equipment allocation, identify areas of improvement, and make informed decisions to enhance resource utilisation. The ability to analyse real-time data empowers managers to identify trends, forecast future demands, and allocate resources efficiently. With data-driven decision-making, companies optimise plant utilisation, reduce downtime, and improve overall operational efficiency.

Foster a culture of accountability:

Fostering a culture of accountability is crucial for achieving and sustaining high plant utilisation rates. This involves creating an environment where all team members, including operators and project teams, understand the significance of their contributions to equipment utilisation. By emphasising the importance of timely reporting, accurate data entry, and efficient equipment usage, managers can instil a sense of responsibility and ownership. Encouraging open communication channels and providing regular feedback can further strengthen this culture of accountability. When all stakeholders are aligned with the goal of maximising plant utilisation, it creates a collective effort towards optimising equipment usage and minimising downtime. Ultimately, a culture of accountability drives efficiency, productivity, and helps the company achieve higher plant utilisation rates.

Provide training and support:

Providing comprehensive training and ongoing support is crucial for optimising plant utilisation. Companies should prioritise equipping operators with the necessary skills and knowledge to operate machinery safely and efficiently, thereby saving time and reducing the risk of injury and equipment damage. Ongoing training programs keep operators updated on best practices, equipment features, and maintenance protocols. By investing in the development of their workforce, companies enhance the capabilities of their operators and improve plant utilisation. Additionally, offering continuous support ensures that operators have access to assistance whenever needed, further enhancing their performance and efficiency. By prioritising training and support, companies create a skilled and knowledgeable workforce that maximises plant utilisation and contributes to overall operational success.

In conclusion, measuring and boosting plant utilisation is critical for the success of construction projects. By implementing a comprehensive tracking system, setting utilisation targets, conducting regular maintenance, optimising scheduling and coordination, embracing data-driven decision-making, fostering a culture of accountability, and providing training and support, companies can achieve higher plant utilisation rates. all-in-one consolidated software is a powerful tool to digitise and streamline operational tasks, facilitating effective utilisation measurement and optimisation. By following these strategies and leveraging the right software tools, operations managers, project managers, and fleet managers can ensure that their construction projects run smoothly and efficiently, ultimately leading to improved plant utilisation rates.

Ready to boost your plant utilisation?

Book an obligation-free demo and see how easy it is with Cloudcon software